ZERØ GRAVITY BY SECCO SISTEMI is a lift and slide steel patio door with Ironlev® magnetic levitation solution which allows the designer to present larger openings in the architecture while maintaining an extremely practical user experience.

Ironlev® technology, in fact, allows for large, extremely heavy doors to move with minimum manual force in a friction free environment, without electricity, as if they were in the absence of gravity.

Ironlev® launches the world's first magnetic levitation elevator.

ZERØ GRAVITY: IronLev® technology meets Secco Sistemi®

ZERØ GRAVITY BY SECCO SISTEMI is a lift and slide steel patio door moved by the IronLev® magnetic levitation solution. This technology allows the designer to project larger openings in the architecture, maintaining an extremely practical user experience.

IronLev® technology is as simple as it is revolutionary, and it aims to "democratize magnetic levitation." This particular passive floatation system allows to move heavy weights almost effortlessly, thanks to its very low friction.

By virtue of its versatility and simplicity, IronLev® can be applied in various sectors, from industrial handling systems to the ØG® system developed by Secco Sistemi.

Secco searched for a technology for opening and closing very heavy windows manually, in a simple and safe way. Now ZERØ GRAVITY® can overcome the constraints of motorization and electricity moving large sliding doors.

ØG® was developed after a long research activity with the IronLev® patent: a peculiar geometry of passive magnets lifts large masses along a small track.

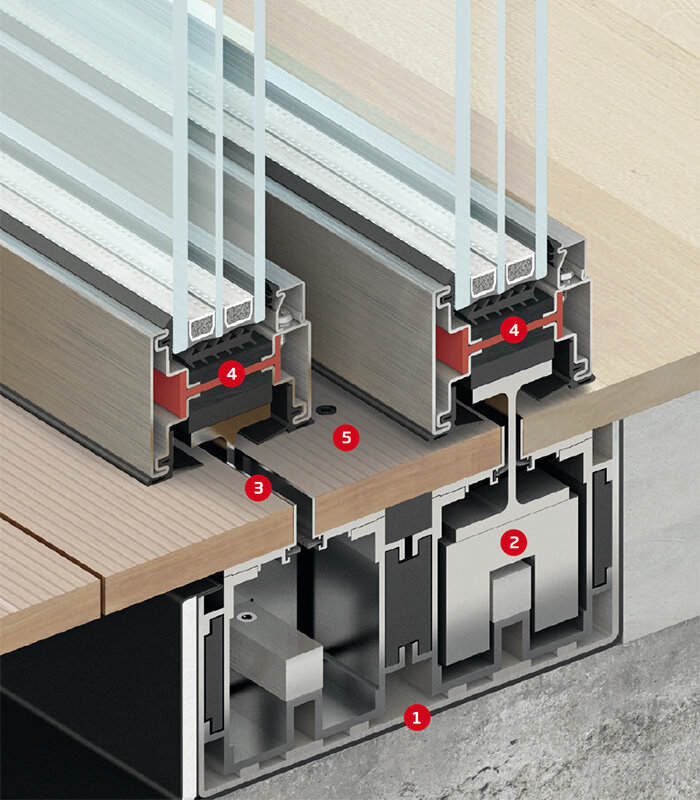

The solution consists of a levitation unit recessed into the floor made of a sliding rail, the IronLev® magnetic pads, and a connection beam to the sash frame.

1. levitation unit - 2. Ironlev® magnetic levitation shoe - 3. sliding slot - 4. window frame - 5. floor. Credits to Secco Sistemi®

The system is accessible for maintenance through removable capping profiles that can be fitted with the same finishes of the floor for a perfect continuity between internal and external floorings.

Only an 8 mm gap, sealed with brushes, remains visible along the all length of the door, completely flush, avoiding any possible tripping.

Along the upper track the system is fitted with mechanisms to counteract the lifting thrust of the magnets and then lower the sash providing locking and tightness.

The system does not require electricity, it works manually even with great weights, up to 1000 kg.

Using this technology, the window is effectively freed from its weight and it slides silently without effort, all because of the inertia of the mass. It can amplify comfort for people and facilitate the opening / closing gesture for any type of user.

Read more about IronLev® and Secco Sistemi ØG® - zero gravity: https://www.ironlev.com/windows

Download Secco Sistemi ØG® - zero gravity brochure: https://cdn.seccosistemi.com/documents/0001/03/0G_A5brochure_ENG.pdf

For press inquiries please write at press@ironlev.com

IronLev®: the first step into transportation revolution

The transportation revolution starts from Italy.

The first prototype of IronLev® has been unveiled: the new levitation technology allows for reutilizing the traditional rails, lifting the wagons without any energy consumption.

This first full-scale prototype of IronLev® has been presented in Spresiano, Treviso (near Venice, in Italy’s northeastern region): it is a revolutionary technology that allows trains to float over the railroad tracks, without touching them and without the need of electrical power. It is a system capable of slashing public transportation’s maintenance and operating costs, democratizing magnetic levitation.

During this special presentation for the press, it was possible to touch firsthand the future of rail transportation: a wagon loaded with a 2 ton-car was moved with a simple light hand pressure, using the same force needed to lift a small backpack.

IronLev® features all the benefits of magnetic levitation (friction reduction, low noise, very high speeds) without compromising on the infrastructural, energetic or safety sides. And notably, IronLev® makes it possible for the first time to make use of magnetic levitation in existing contexts of application, like high speed trains and urban subways.

“Magnetic levitation is a technology that has been studied for over 50 years” – states IronLev®’s President and co-founder, Adriano Girotto – “and many companies have been unsuccessfully trying to apply it to the public transportation sector, failing due to the enormous setup and maintenance costs of the lines. IronLev solves this key problem, reducing the energy and infrastructural costs and allowing us to reuse and revamp the over 1,5 million kilometers of existing railways, all around the world”.

Differently from the previous maglev systems, IronLev® does not utilize electricity to lift the wagons, bringing remarkable energy savings when compared to both traditional rail systems and to the previous maglev technologies.

reversed U-shaped sliders

The IronLev® architecture is based on a special configuration of magnets that are embedded in reversed U-shaped sliders, wrapping around the rail without touching it, and generating a self-sustaining solution without the need to push electricity into the system. Moreover, by completely surrounding the track, IronLev® sliders eliminate any derailment risk.

IronLev® is a safe system from the environmental perspective too: the magnetic field is entirely restrained in the few centimeters of space between the rail and the track, and does not generate any external interference, respecting both the environment and passengers’ health.

Conceived to revolutionize the rail transportation industry, IronLev® can be applied to many other contexts beside the traditional transportation, including the entertainment industry (monorails, rollercoasters, ropeways), industrial automation, and even automatic parking systems, elevators and next-generation transportation systems.

“Born to reinvent the rail-based transportation, IronLev®enables many more applications of magnetic levitation in many different domains” declares Luca Cesaretti, co-founder of IronLev® “In the past months” – adds Lorenzo Andrea Parrotta, co-founder, – “we are realizing that there is a very transversal attention to this new type of technology. We are gathering very strong interest for the application of IronLev® in several industrial sectors that we were not even thinking of approaching.”

The next steps for the IronLev® technology will include the engineering of a complete and fully functional levitating wagon system. To meet this goal, the technical team is moving towards an agreement with an industrial partner that will support the further developments.

IronLev® was born in IronBox srl, the result of the joint-venture of two Italian companies: Girotto Brevetti, a Treviso based R&D engineering company with over 10 years of experience and Ales Tech, a Pisa-based startup that is actively working in the Hyperloop ecosystem.

For press inquiries please write at press@ironlev.com